Coma News

Community

News

HOME > News

Ultra-High-Temperature Ceramics (UHTCs)

Ultra-high-temperature ceramics (UHTCs) are a class of advanced ceramic materials distinguished by their exceptional stability and performance under extreme environments. Defined by melting points above ~3000 °C, robust mechanical properties, and good chemical resilience, UHTCs have become critical enabling materials for next-generation aerospace, hypersonic, and energy conversion applications. Their ability to maintain structural integrity at temperatures where most metals and conventional ceramics fail makes them indispensable for thermal protection systems (TPS), leading edges, rocket nozzles, and nuclear reactor components.

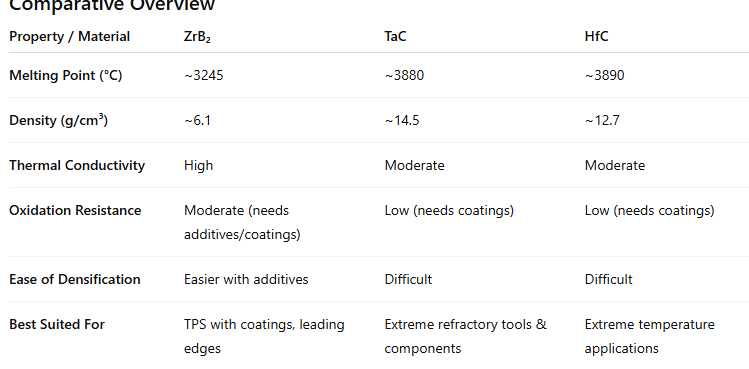

UHTCs are typically transition-metal borides, carbides, and nitrides. Among these, Zirconium Diboride (ZrB₂), Tantalum Carbide (TaC), and Hafnium Carbide (HfC) are the most studied due to their high melting points, stiffness, and thermal stability. However, despite their shared categorization, these materials differ significantly in physical properties, oxidation resistance, and processing challenges—each offering trade-offs that determine their suitability for specific applications.

Key UHTC Materials: Comparison and Characteristics

Zirconium Diboride (ZrB₂)

Melting Point: ~3245 °C

Properties: High thermal conductivity (~60–70 W/m·K), good electrical conductivity, relatively low density for a UHTC (~6.1 g/cm³).

Strengths: Excellent balance of mechanical strength and thermal properties; easier to densify (compared with carbides alone) when processed with additives (e.g., SiC).

Challenges: Susceptible to oxidation above ~900 °C in air, forming volatile boron oxides; requires protective coatings or sintering aids to enhance oxidation resistance.

Applications: Thermal protection systems, leading edges with oxidation barriers, hypersonic components.

Tantalum Carbide (TaC)

Melting Point: ~3880 °C (among the highest of all carbides)

Properties: Exceptional refractoriness, high hardness (~20–24 GPa), good wear resistance.

Strengths: Superior high-temperature stability and hardness compared with most UHTCs; high density (~14.5 g/cm³) contributes to robust mechanical behavior.

Challenges: Very high density poses weight penalties for aerospace; extremely difficult to sinter to full density without advanced methods (e.g., hot pressing, spark plasma sintering).

Applications: Ultra-refractory components, tool materials, extreme wear environments.

Hafnium Carbide (HfC)

Melting Point: ~3890 °C (highest among known binary carbides)

Properties: Extremely high melting point and excellent chemical stability; high hardness and modulus.

Strengths: Best refractory limit among carbides; stable at temperatures where other ceramics degrade.

Challenges: Like TaC, difficult to fully densify due to strong covalent bonding and low diffusion; oxidation resistance is limited (oxides form above ~800–1000 °C), mandating environmental protection strategies.

Applications: Hypersonic leading edges, rocket nozzles, high-temperature furnace components.

Preview

Preview Next

Next